Fully automated fire protection: onoff expands range of services

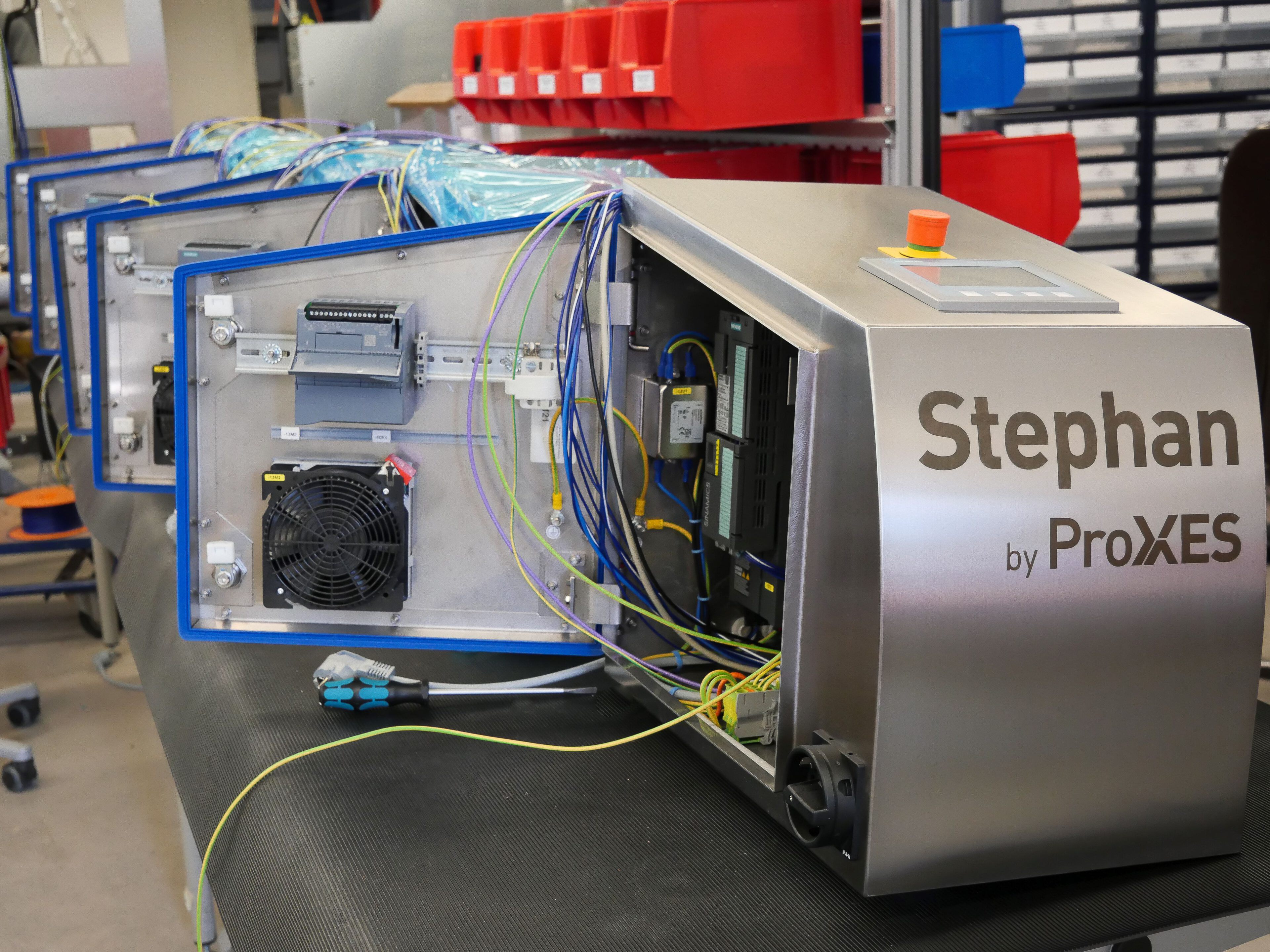

Around one third of all fires in industry are caused by electricity. They often originate inside electrical equipment or control cabinets, where they are difficult to detect and inaccessible. onoff automation services gmbh, which has 30 years of expertise in control cabinet construction, now offers its customers the right fire protection solution: the installation of an automatic miniature fire extinguishing unit (AMFE). This extinguishes the fire at its source, because thanks to its small size, the extinguishing unit can be placed directly at the source of danger – in the control cabinet, for example.

24/7 fire protection thanks to AMFE

The fire is extinguished in a matter of seconds, thanks to the use of thermal ampoules that trigger a mechanism when a certain temperature is reached, releasing the extinguishing agent directly at the origin of the fire. The automatic device is connected to the equipment to immediately cut off the power supply, preventing further damage.

onoff relies on the fully automated AMFE systems offered by the company JOB, which are characterized by their reliability, robustness and versatility. The AMFE series includes six different sizes from 0.06 to 1.5m3 extinguishing volume and different triggering mechanisms, so that the right extinguishing device is available for every application. The onoff team takes care of the installation in new switchgear cabinets, which are assembled in their own workshop at the Wunstorf site, or offers retrofitting for existing switchgear. Regular maintenance and testing of the extinguishing devices is also part of the new range of services.

onoff relies on the fully automated AMFE systems offered by the company JOB, which are characterized by their reliability, robustness and versatility. The AMFE series includes six different sizes from 0.06 to 1.5m3 extinguishing volume and different triggering mechanisms, so that the right extinguishing device is available for every application. The onoff team takes care of the installation in new switchgear cabinets, which are assembled in their own workshop at the Wunstorf site, or offers retrofitting for existing switchgear. Regular maintenance and testing of the extinguishing devices is also part of the new range of services.

Frank Jahr, Managing Director of onoff automation services gmbh, is pleased about the expansion of the portfolio: “With AMFE, we are offering our customers a new, extremely important service. The TÜV-certified extinguishers meet the highest standards according to ARGE guidelines and are an important component of a holistic fire protection concept to minimize the dangers for man and machine. Through the JOB systems, we can individually address the specific requirements of our customers and find the right extinguishing device for every plant and every piece of equipment.”